For my next trick I will perform a beautifully sewn pocket for a pair of shorts! I recently went through the task of making three pairs of shorts for a client and thought I would share with you my method of creating the inseam pocket. I'm assuming that you already have a pattern for the pocket and I'm just taking you through the sewing steps. If you would like a tutorial on how to make a pattern for this type of pocket just shout and one may be provided!

MATERIALS NEEDED:

- Fabric and shorts/trouser pattern

- Lining

- Scissors

- Sewing machine

- Pins

TUTORIAL

1. Grab all your pattern pieces for the shorts as we are about to begin! So you should have a pocket lining (lining fabric), a pocket backing (lining fabric) and a facing (fashion fabric), like so:

2. To make the pocket nice and neat and professional finished which is what we all want we need to finish the edge of the facing. You only need to do the edge of the facing that will be inside the pocket so don't bother with the side seam edge or top or bottom. I use a serger to finish the edge but you can use a zigzag stitch on a normal sewing machine.

3. Pin the beautifully neat facing to the pocket lining along the side seam edge of the pocket lining and sew in place with a normal straight stitch.

4. Next on the agenda is attaching the pocket backing to the front of your garment of choice. Pin the two straight edges right sides together and sew with a plain old regular straight stitch.

5. To make a lovely crisp edge for the pocket understitching is the thing to do. So first you'll need to finish the raw edge with either a serger or zigzag stitch. Then iron the seam flat so you have a nice edge to work with then to the sewing machine once more.

From the wrong side of the fabric sew the finished raw edge to the backing lining. This can be quite tricky so go slowly.

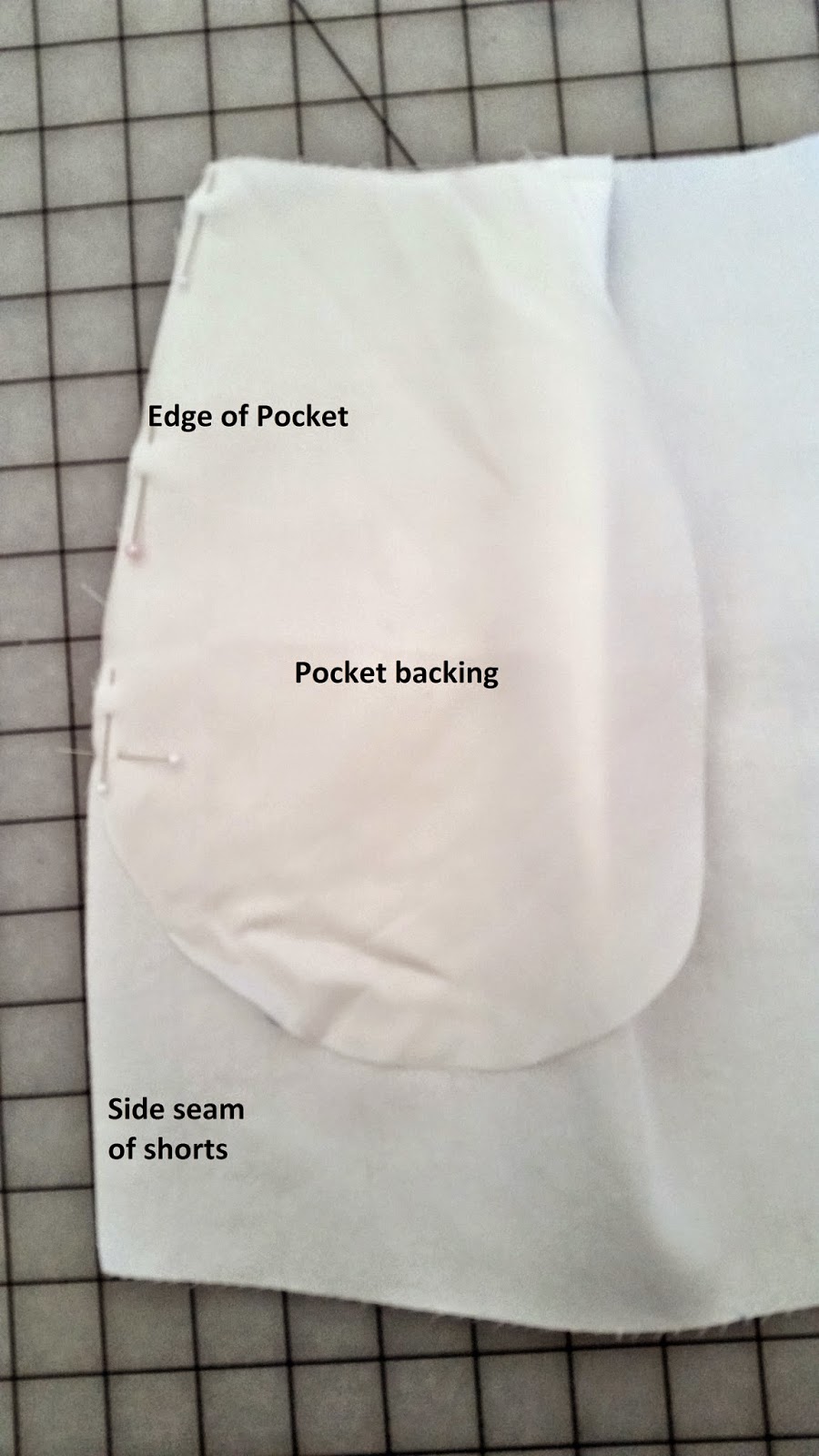

6. Now the pocket backing will meet its friend for life the pocket lining with attached facing! Mark on the pocket lining where the edge of the pocket will go to, I do this with a pin but you can use chalk or anything that marks.

Match up the pocket backing and lining and pin around the edge. Don't worry if its not an exact match as you can trim around the edges later. Make sure that the pocket backing is lying flat and is in the correct position on the lining.

7. Sew the pocket lining and pocket back together around the edge using a long basting stitch. Once sew together double check to make sure everything is lined up properly by folding the pocket over to to the wrong side of the short front. You should have a small triangle of the facing showing.

8. Easy step of just serging or finishing the edge of the pocket pouch so its all neatly finished on the inside of the garment. I use my serger again but a zig zag stitch would also do the job.

9. Turn the pocket to its correct position so its on the wrong side of the shorts and pin the top of the pocket lining to the the top of the front short ie where the waistband will go. Also pin the side seam of the pocket to the side seam of the shorts. Make sure at this point that the pocket is laying flat.

|

| View from right side |

|

| View from wring side |

Baste that down then you are ready to construct the rest of your garment with a perfectly sewn pocket!

I hope this all made sesne, if not I am happy to answer any questions so fire away!!